Check out nature and you'll find the best ideas.

The production process releases heat and kerosene in the buildings, which leads to overheating throughout the year and affects air quality. The intention of this project is to maintain ideal air quality and approximately constant and comfortable temperatures. Our role models in this project are natural physical phenomena.

Immerse yourself in a pool of room air filled with fresh air.

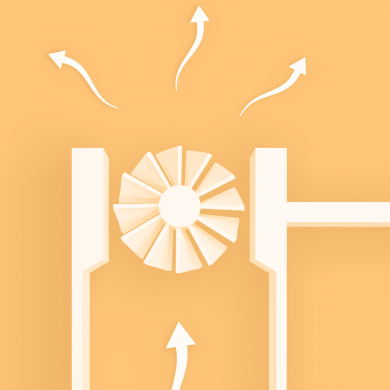

The ventilation systems are evenly distributed in the roof to keep air channels short and to supply the air evenly and according to demand to the production area. The incoming air is brought in close to the ground via diffusion outlets at low velocity. In this system, known as stratified ventilation, floor-level penetration of incoming air forces warm and used room air upward, forming a stable indoor air pool of fresh air in the employee lounge area.

Feel a cool breeze - almost like at the sea.

In summer, environmentally friendly adiabatic cooling is added when needed for peak load cooling. This type of cooling, also called evaporative cooling, uses a natural cooling effect that occurs simply through the evaporation of water. In the process, dry, warm air absorbs water as it flows through the Coolstream, reducing the air temperature. At an outside temperature of over 30°C, the air can be effectively cooled by more than 10°C - without polluting the environment!